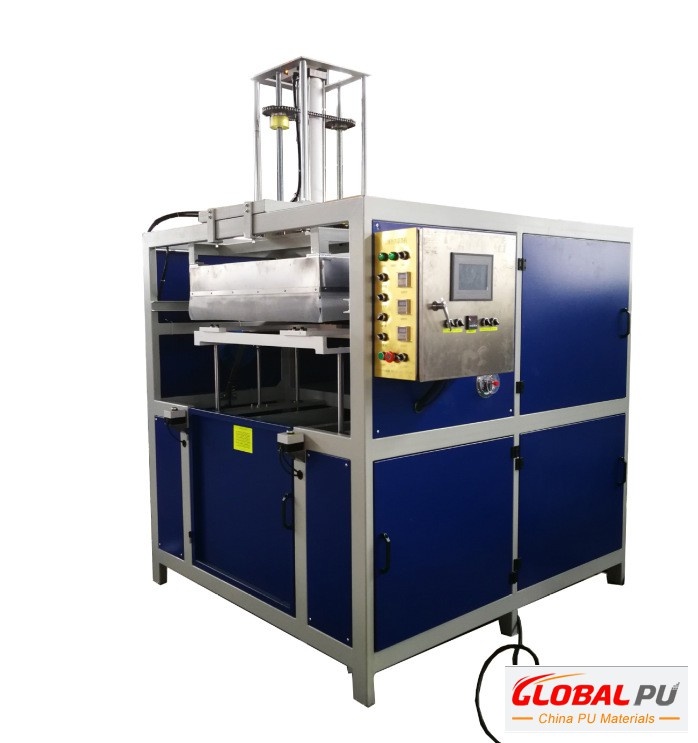

| Automation: | Automation | Computerized: | Computerization |

| Applicable raw materials: | Color Printing Plastic Sheet | Applicable industries: | Toys |

| Shape Type: | Single male mold forming | Style: | Horizontal |

| Brand: | long | After-sales service: | One year warranty |

| Forming Length: | 800 | Forming Width: | 600 |

| Maximum Forming Depth: | 200 | Molded Area: | 500*700 |

| Production Rate: | 10s | Working Air Pressure: | 0.5-0.7MPA |

| Motor Power: | 3.5kw | Model: | PU Ball Blister Machine |

| Have licensable private labels: | Yes | Yield: | 32 |

Detailed introduction of "composite foam toy ball blister machine PU soft ball shell color printing blister machine"

Purpose

Used for PU foam toys (foam balls, foam frisbees, globes, bowling balls, volleyballs, footballs, dolls, etc.) .

< img height="523px" src="https://www.globalpu.net/file/upload/202206/30/141252301.jpg" srcid="bnvQFCDMrWlV" tempid="57495684" width="698px">< br>

Rationale:

Cut the printed plastic sheet to the size matching the mold, then put it on the mold and seal it with the mold, and then heat the plastic sheet to soften, By vacuum,The plastic is stretched close to the surface of the mold, and after cooling and hardening, the plastic becomes the same hemispherical shape as the mold.

Features:

1. This machine is a semi-automatic structure, clip Plastic, the finished product is done manually,Other actions are done automatically.

2. This machine is a single-station model, with a heating furnace and a mold-loading station.< /strong>

3. Using far-infrared ceramic heating elements, which can be individually controlledand display The temperature of each heating element is easy to adjust the temperature.

4. The power of this machine is pneumatic, and it needs to be equipped with an air compressor for normal use. The air compressor is self-configured by the user.

5. This machine needs to be equipped with a plastic mold to use, and the plastic mold is produced according to the customer's own requirements, and the customer is responsible for it. Our company can also process molds according to customer requirements.