| In stock: | Yes | Authentication: | EU RoHS |

| Material: | Polypropylene | Pattern: | Glue |

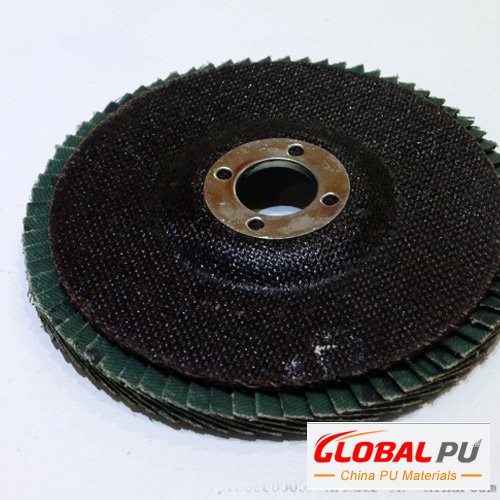

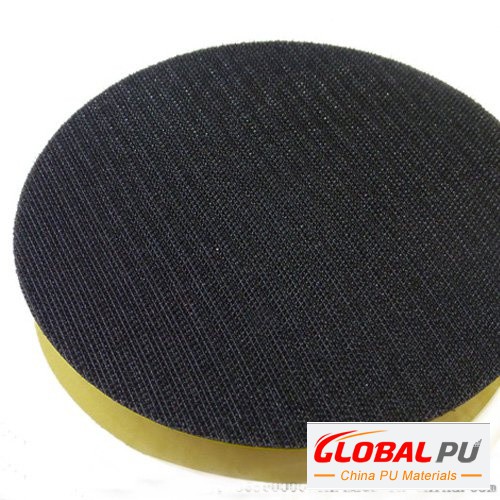

| Apply: | Polishing Disc, metal, Rubber, Plastic | Model: | Jd-9381 |

| Specifications: | 5kg/barrel 15kg/barrel | Trademark: | Nine |

| Packaging: | 5kg/barrel 15kg/barrel | Yield: | 9681522 |

Detailed introduction of "polishing disc glue JD-9381 polishing disc adhesive manufacturer"

Polishing disc glue JD-9381 polishing disc adhesive manufacturer

Polishing disc glue JD-9381

【Features】

1. A single-component polypropylene multi-purpose glue developed by the introduction of international technology and the main body of imported reinforced resin and polymer nanomaterials

2. Passed the EU ROHS standard, no triphenyl solvent

3. Easy to use and quick positioning

4. High bonding strength, room temperature curing

5. Good acid and alkali resistance, corrosion resistance

Polishing disc Glue application range:

Widely used in home appliance industry, machinery, electronic packaging materials, brush making, craft gifts and other industries

[How to use 】

1. Surface treatment: clean the surface of the adherend to ensure that the surface of the adherend is dry, No oil, no dust

2. Glue: put polishing disc glueJD-9381Apply directly to the surface of the adherend,Be careful to stick The junction glue is evenly applied and must be glued on both sides

3. The glue thickness is 0.05-0.08mm, hanging span>5min-10 min, after the solvent evaporates (subject to non-sticky hands) span>, press fit and press flat Tight

4. The ideal is to heat the adhesive surface after gluing (the temperature is 60-80 degrees, and the heating time is 2-3 minutes) Directly glue the two surfaces and press to make them in close contact, remember, be sure Flatten the adhesive surface to remove any air bubbles between the adhesive surfaces.

Surface treatment: The surface of the adherend is cleaned to ensure that the surface of the adherend is dry, free of oil and dust;< /span>

If it is a loose material, it can be applied for a second time, and then aired15min-25min, directly glue the two surfaces, and press to make it in close contact, P< /span>P The glue can be placed at room temperature24H to achieve high strength, and the strength can be reached after 72 hours.