| In stock: | No | Authentication: | CE ISO |

| Brand: | Yinyan Chemical | Application: | Chemicals |

| Material Type: | Medium to high viscosity, pasty material | Applicable materials: | Medical glue, anaerobic glue, slurry, etc. |

| Power Type: | Electric | How it works: | Shear mixer |

| Barrel movement: | 3D | Structure: | Planetary Mixer |

| Product Type: | New | Layout form: | Vertical |

| Charge Amount: | 2000L | Amount of processing per time: | Customizable |

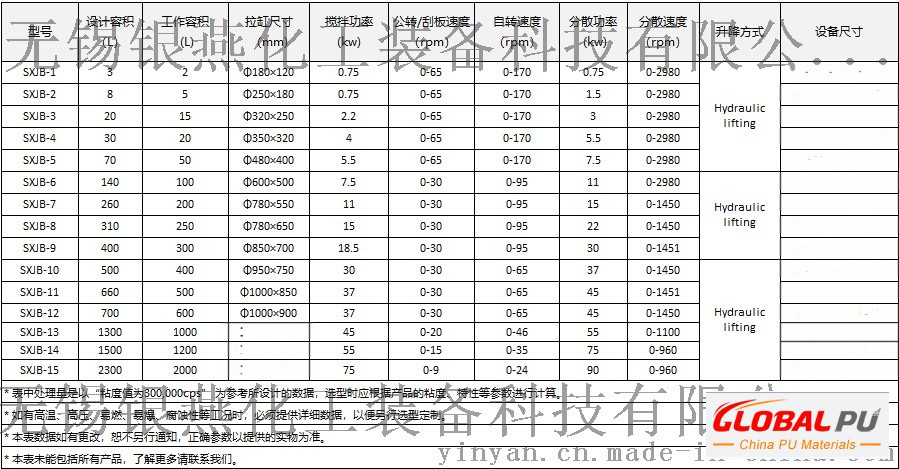

| Production Capacity: | 2-2000 | Discharge method: | Screw Extrusion |

| Specifications: | Custom | Trademark: | Wuxi Yinyan |

| Packaging: | Wooden Box | Yield: | 1000 |

Detailed description of "Adhesive Adhesive Vacuum Explosion Proof Planetary Power Mixer"

Adhesive Adhesive Vacuum Explosion Proof Planetary Power Mixer Mixing The paddle rotates at the same time as it revolves, so that the material in the tank circulates up and down and around, so that the mixing (kneading) effect can be achieved in a very short time. The inner wall of the tank is finished by a large vertical lathe, and then automatically polished by a large polishing machine to ensure that the movable scraper on the planetary box completely scrapes the material on the inner wall of the tank when it rotates. This machine is especially suitable for dissolving, mixing, kneading and reaction process from powder to high viscosity and high density materials. Widely used in chemical products such as batteries, organic silica gel, inks, dyes, adhesives, high viscosity coatings and so on.

Adhesive Adhesive Vacuum Explosion Proof Planetary Power Hybrid Features of mixer products

1. Low clearance The gap between the paddle and the paddle (4-6mm), the paddle and the barrel wall (3-4), and the paddle and the bottom of the barrel (2-3mm) is low, and the stirring paddles are mutually The precise gap between the mixing paddle and the inner wall of the mixing tank is that the mixing tank has no dead angle and has a high kneading effect, so that the materials can quickly penetrate and knead each other in a short time.

2. Low noise Precision machining of parts, professional tooling, parts High coordination, low wear, smooth operation and low noise; under full load operation, a low-noise working space is created.

3. Corrosion-resistant zero leakage Corrosion-resistant mechanical seal plus soft, Statically sealed, the planetary transmission box adopts a fully sealed structure, and the all-round sealing concept improves the sealing performance by 50% on the traditional basis; the vacuum degree can reach -0.098MPa, and the vacuum retention degree is high, ensuring the stirring process.

4. High strength According to different mixing processes (wet mixing, dry and wet mixing), after strict strength calculation, it is suitable for high viscosity, high solid content battery positive and negative slurries, binders and other products mixed reactions are used.

5. High integration The links of premixing, stirring, turnover and filtration are seamless and quick-release docking, and there is no contact with air. It can be fully controlled by PLC, and the speed, temperature, lifting and vacuum systems can be integrated on a panel for control.

6. Strong optionality Double twist, double paddle, double butterfly, triple twist, double straight frame agitator and lift bucket or lift beam can be selected to meet the production needs of different working conditions.