"Manufacturer produces tpr thermoplastic elastomer tpr elastomer raw material anti-static plastic raw material" parameter description

| In stock: | Yes | Authentication: | American Standard |

| Type: | TPR | Grade: | TPR Antistatic Plastic |

| Processing Level: | Hollow grade, extrusion grade, rotomolding grade | Feature Level: | High temperature and low temperature resistance |

| Usage Level: | Fill grade, electrical and electronic components | Model: | TPR Antistatic Plastic |

| Specifications: | 25KG | Trademark: | American Standard |

| Packaging: | American Standard |

Detailed introduction of "manufacturers produce tpr thermoplastic elastomer tpr elastomer raw material anti-static plastic raw material"

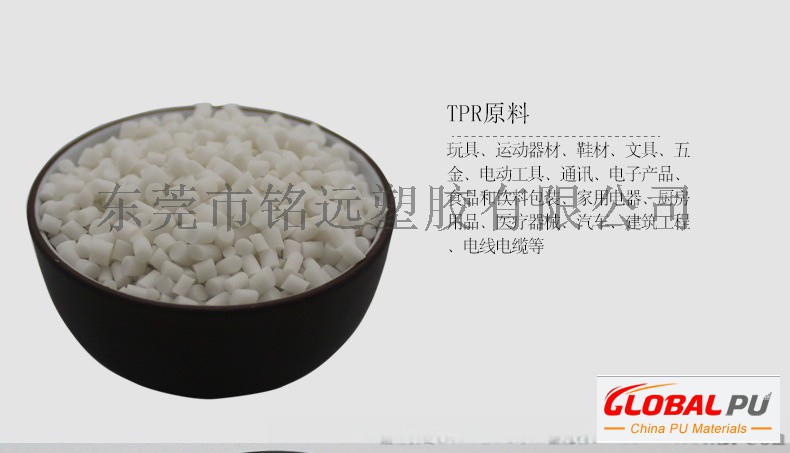

※Product name: TPE|TPR material encapsulated Tritan plastic

※Basic product introduction:

Tritan TPE, TPR material.

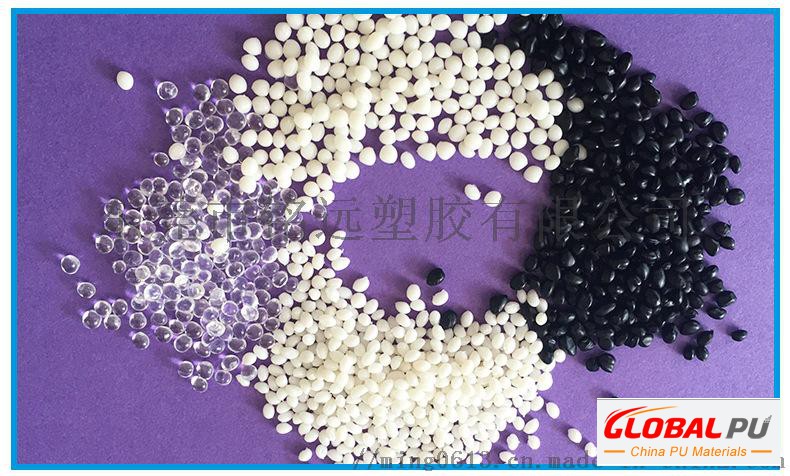

1. The hardness is 50~85A, and the appearance is translucent or solid color particles;

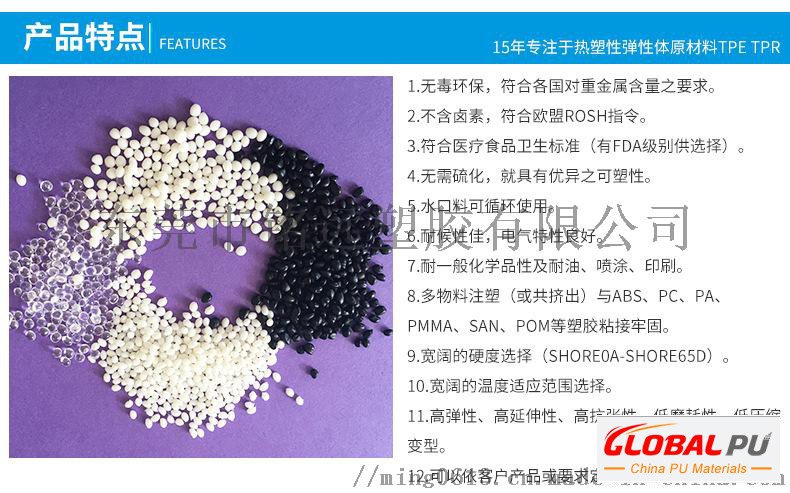

2. Odorless, meets food-grade testing standards;

3. Temperature resistance -50~90℃;

4. Excellent processability.

Recommended overmolding temperature: 180~200℃.

Represents applications: food cutlery packaging, cup lids, etc.

※Introduction to molding:

Shaping method:

extrusion and injection molding: just use a screw extruder (including general injection molding and two secondary molding); the equipment is general injection molding machine \ two-color injection molding machine, etc.

Other molding methods: blow molding, salivation calendering.

about the shrinkage rate of TPR - 1.5~2%.

※Material storage:

TPR pellets should be placed in a cool and dry place;< /p>

Opened materials should be packed in a timely manner after being picked up, and placed to be contaminated by moisture and impurities;

For the TPR material that has been placed for a long time (more than 1 month), it is recommended to bake the material and then process it.